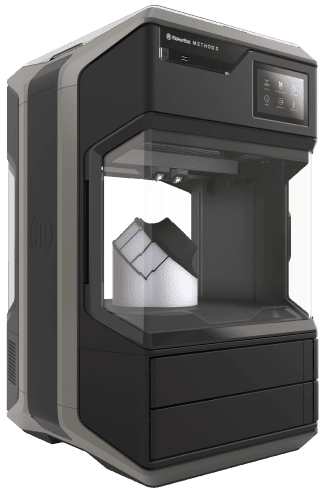

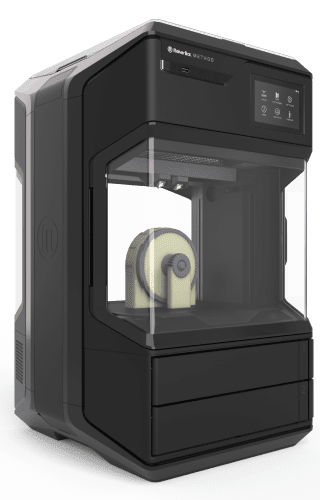

PROFESSIONAL 3D PRINTER

UltiMaker Method 3D Printer

Powered by Innovation

Introducing METHOD, a Manufacturing Workstation. This desktop Industrial 3D Printer replacement prints complex and durable parts for end-use assemblies and manufacturing tools. Print using a wide variety of materials, including Carbon Fibre and ABS, while achieving amazing dimensional accuracy.

What sets Method apart?

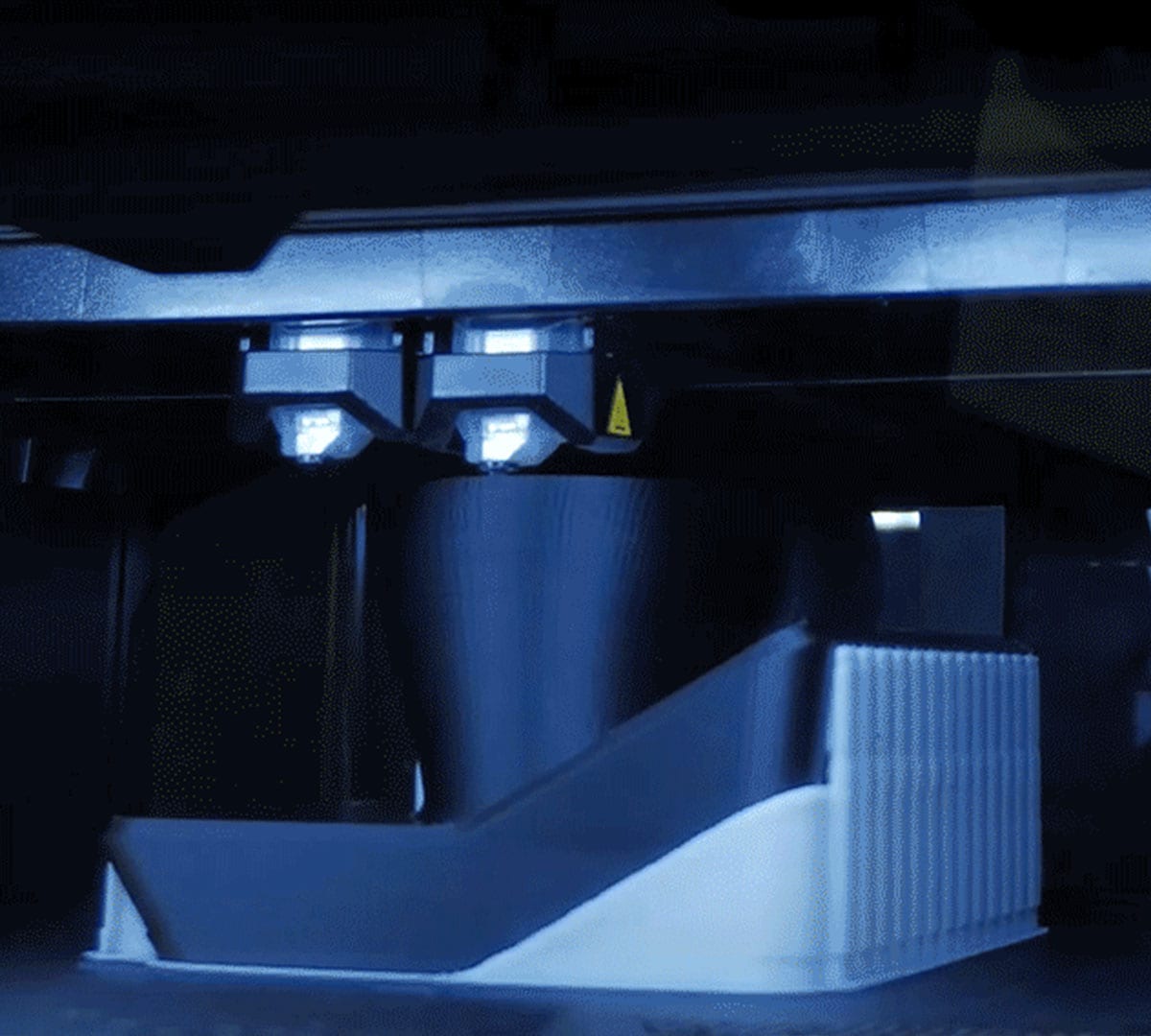

Circulating Heated Chamber

At the heart of the METHOD platform is the circulated heated build chamber, exclusive to UltiMaker. Our heated build chamber helps you to achieve dimensional accuracy and high strength manufacturing grade parts. METHOD

has a 60C heated build chamber, while the METHOD X has a 100c build chamber.

– A Heated Chamber produces stronger more durable parts than a heated build plate.

– Get consistent strength in three axis with recirculating heat on every layer.

– Achieve better mechanical and thermal properties than modified desktop 3D printer formulations.

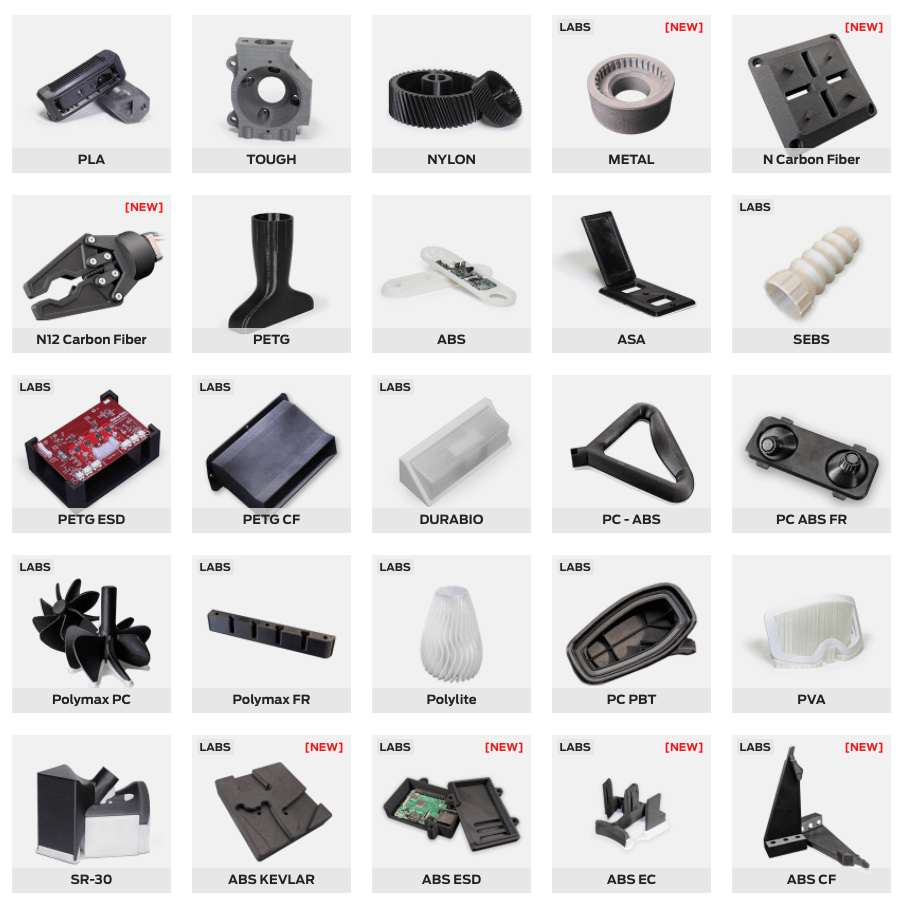

Advanced Engineering Materials

The METHOD platform can print with a wide variety of advanced engineering materials. Our open [platform allows you to access unlimited materials with MakerBot Labs.

– Print with official MakerBot materials including Nylon Carbon Fibre, ABS, Nylon, PC-ABS and SR-30 – each carefully tested for thousands of hours to achieve engineering standards of printed part dimensional accuracy and strength.

– Access unlimited materials with an Open Materials Platform enabled by LABS. Print advanced materials, such as ABS Carbon, TPE (flexible), PETG ESD, and PC.

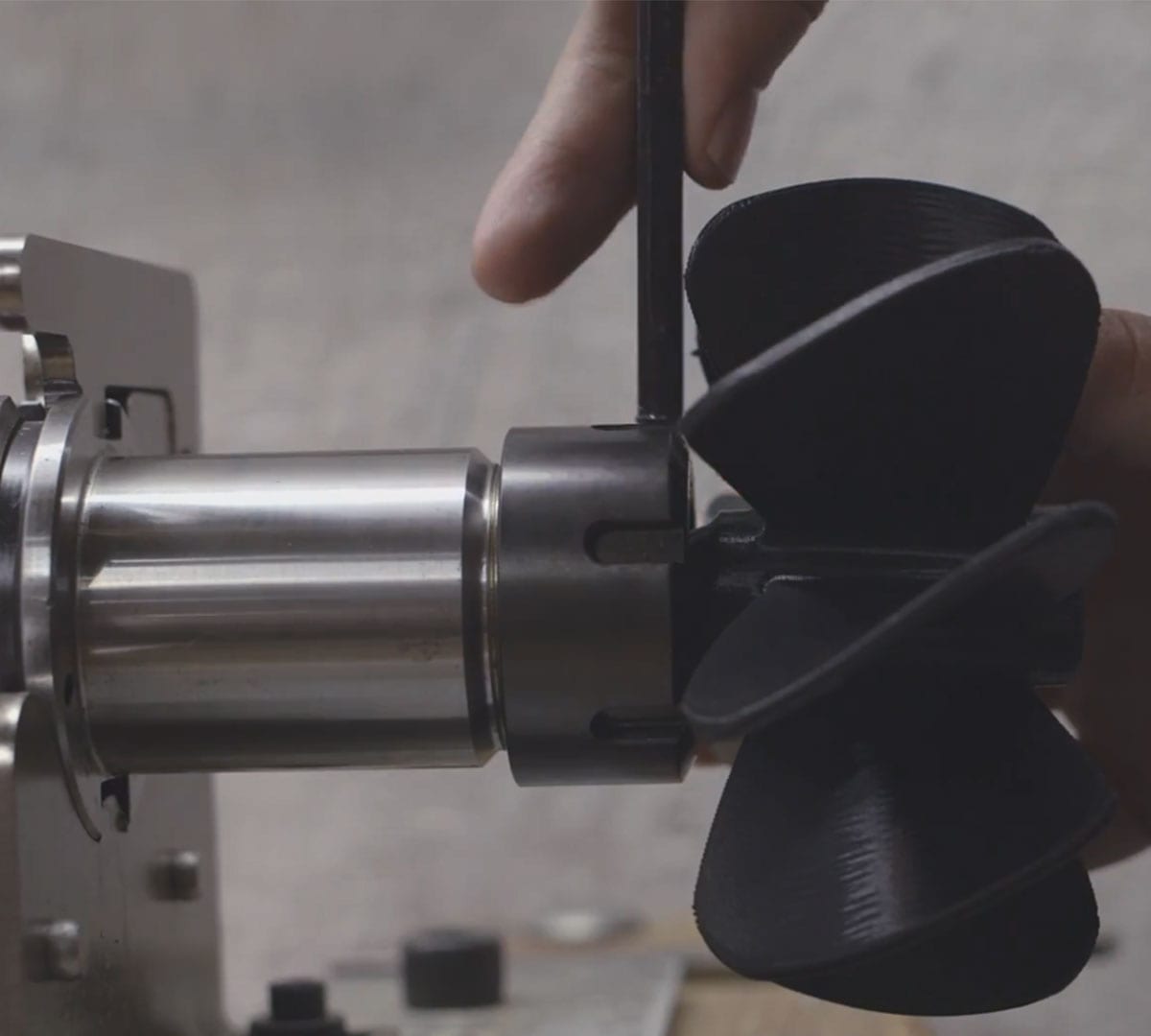

Manufacturing Grade Parts

The UltiMaker METHOD platform can print with a wide variety of advanced engineering materials. Our open platform allows you to access unlimited materials with MakerBot Labs.

– Print with official UltiMaker materials including Nylon Carbon Fibre, ABS, Nylon, PC-ABS and SR-30 – each carefully tested for thousands of hours to achieve engineering standards of printed part dimensional accuracy and strength.

– Access unlimited materials with an Open Materials Platform enabled by MakerBot LABS. Print advanced materials, such as ABS Carbon, TPE (flexible), PETG ESD, and PC.

Dimensional Accuracy

A key feature of METHOD 3D printers is the finished part dimensional accuracy. This allows METHOD to print complex geometries that are impossible to print with advanced materials on a regular Desktop 3D printer.

– Enabled by Stratasys SR-30 soluble supports.

– The only printer in its class to guarantee finished part dimensional accuracy ± 0.2mm (± 0.007in).

– Print complex assemblies that fit with tight tolerances – every time.

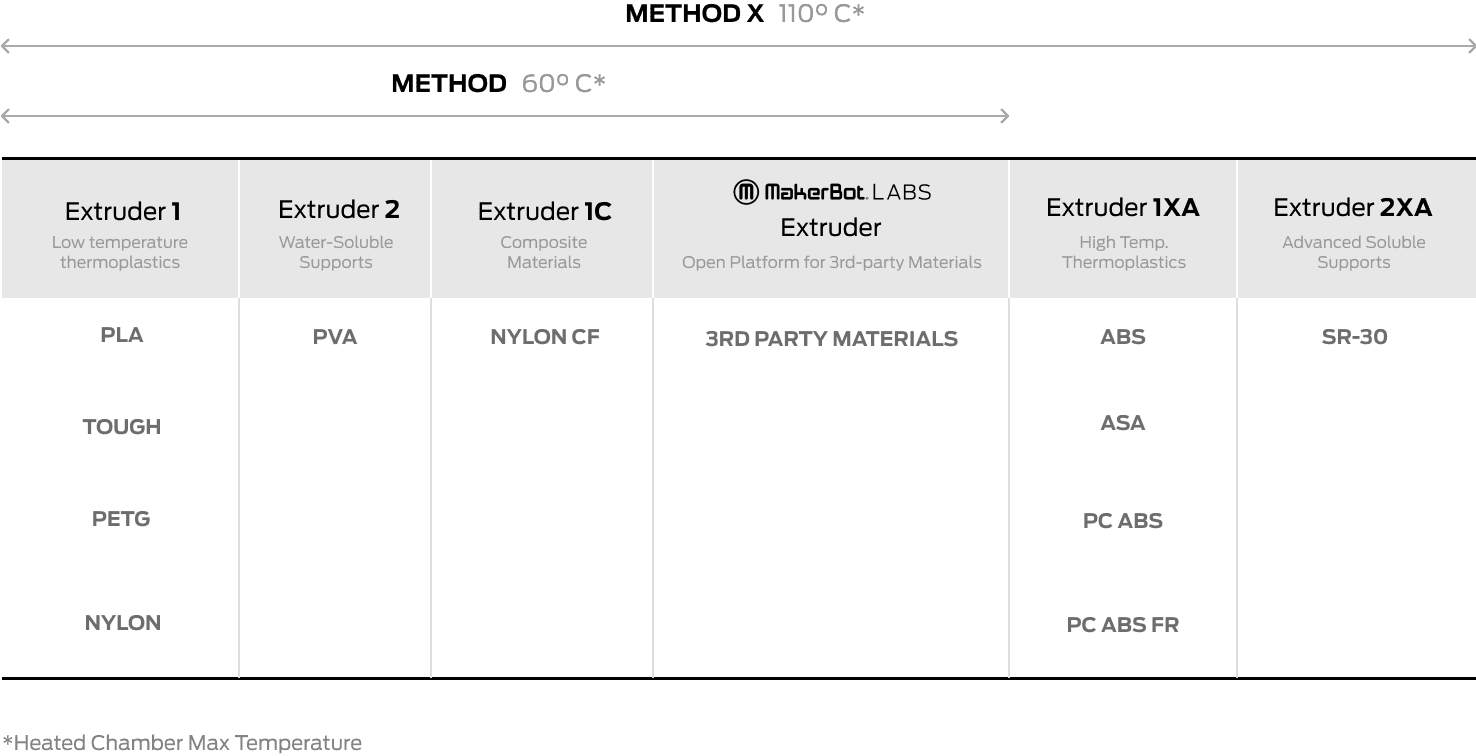

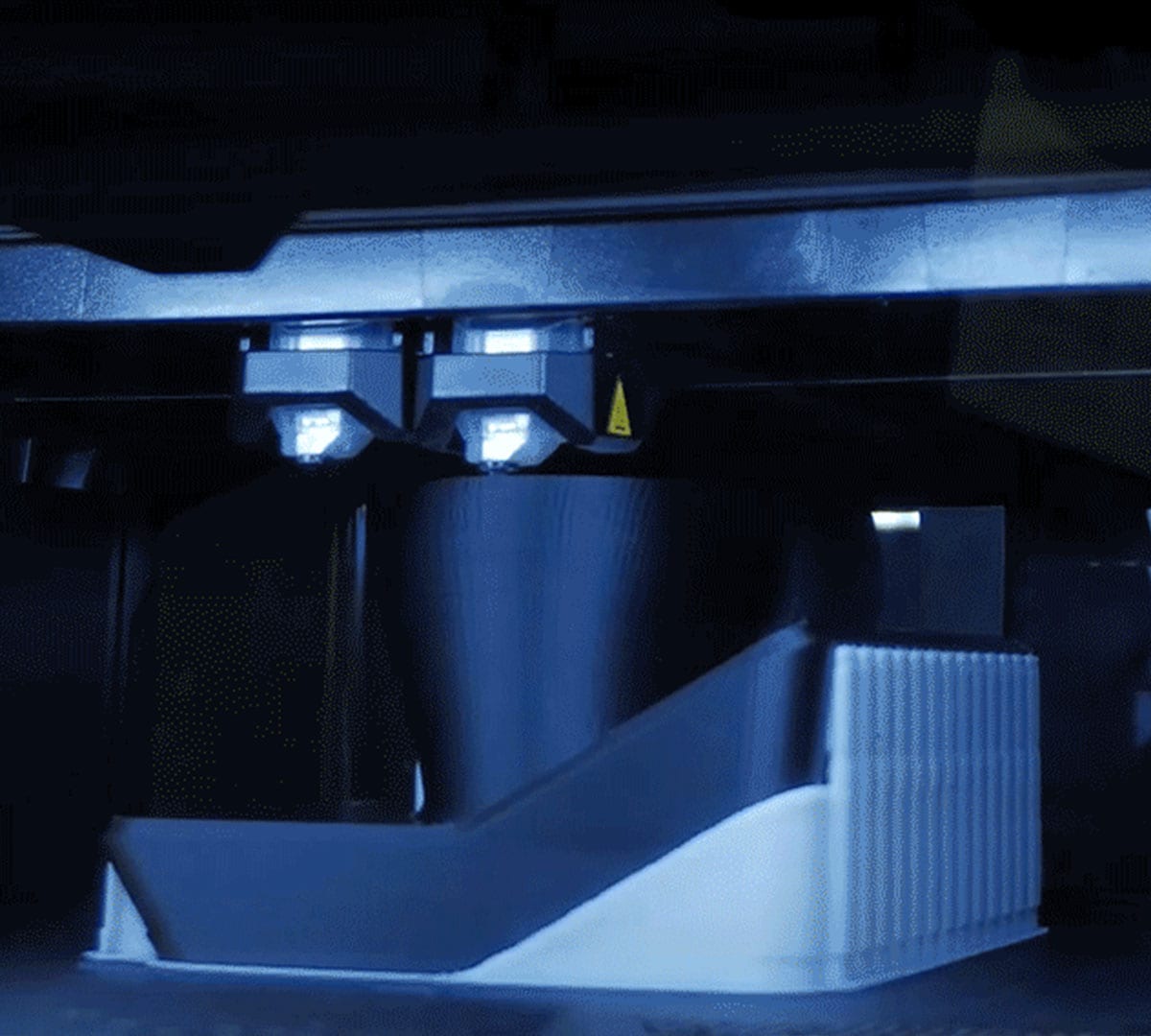

Dual Performance Extruders

The METHOD dual performance extruder system is built from the ground up to accelerate print times while providing dimensional accuracy.

– Smart Sensors for material management and print protection.

– Greater Torque with a 19:1 dual-drive gear ratio.

– Lengthened thermal core with less than 60 second heat up time.

Dual Performance Extruders

The METHOD dual performance extruder system is built from the ground up to accelerate print times while providing dimensional accuracy.

– Smart Sensors for material management and print protection.

– Greater Torque with a 19:1 dual-drive gear ratio.

– Lengthened thermal core with less than 60 second heat up time.

Wireless Printing & Monitoring

MakerBot Print + MakerBot Cloud work hard so you don’t have to. With over 25 supported native CAD file types, you can focus on your next design rather than messing around with plugins and conversions. You can also remotely print, monitor and control your device from anywhere in the world.

Automated & Tinker Free

MakerBot boast the most stream-lined workflow in the industry saving you time and putting an end to tinkering.

– Automated material handling, build plate leveling, and extruder calibration.

– Keep your projects moving and enjoy enjoy peace of mind with our leading in-house

customer support plus local Australian warranty (link to warranty).

– Seamless CAD integration with AUTODESK INVENTOR, AUTODESK FUSION 360, Onshape and Solidworks.

Low Total Cost of Ownership

METHOD is designed from the ground up to deliver industrial quality performance at a fraction of the cost of ownership of an entry level Industrial 3D printer.

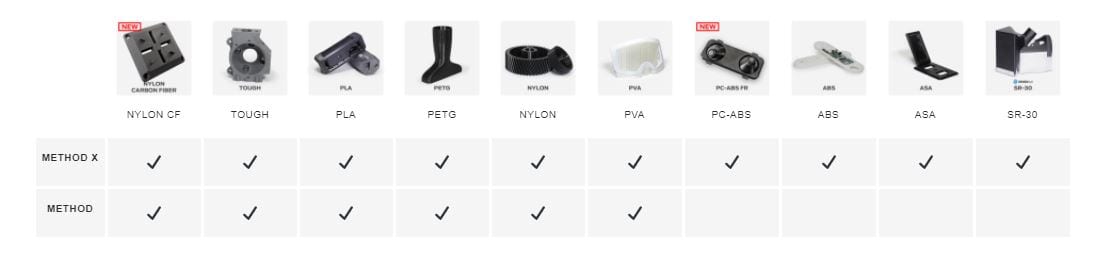

Materials for METHOD

METHOD materials are made to exacting diameter and quality specifications. They are also tested rigorously for the highest reliability and measurably accurate parts.

METHOD prints a selection of UltiMaker polymers to guaranteed dimensional accuracy spec with the aid of a 60°C heated chamber.

METHOD X prints the Full catalog of UltiMaker polymers and composites with superior accuracy and strength in a 110°C heated chamber.

Replace metal parts with 3D printed Carbon Fibre on UltiMaker METHOD or METHOD X Carbon Fibre Edition.

ULTIMAKER METHOD TECH SPECS

PRINTING

Print Technology

Fused Deposition Modeling

Print Heads

2

Dimensional Accuracy

+/- 0.2mm

Layer Resolution

100 microns [0.0039 IN]

Build Speed

Up to 2x faster than desktop 3D printers2

Max Material Flow Rate: ~50 mm3 per sec

Print Head Travel Speed: Up to 500 mm per sec

Print Modes Tuned & Optimized for:

100 microns – High Quality Print Mode (Coming Soon)

200 microns – Balanced Print Mode

Maximum Build Volume

19 L x 19 W x 19.6 H cm / 7.5 x 7.5 x 7.75 in single extrusion (print settings coming soon)

15.2 L x 19 W x 19.6 H cm / 6.0 x 7.5 x 7.75 in dual extrusion

PRODUCT TESTING

Test Hours

220,000+ total testing hours

(system reliability, subsystem, and print quality)

OPERATION

Ambient Operating Temperature

15 – 26º C / 59 – 78º F, 10 – 70% RH non-condensing

Storage Temperature

0 – 38º C / 32 – 100º F

Printer Automation

Automatic Z Calibration, Automatic Nozzle Calibration, Automatic Material Loading

SAFETY & COMPLIANCE

FCC

EMC

Low Voltage Directive 60950-1, 62368

SIZE & WEIGHT

Product Dimensions

43.7 L x 41.3 W x 64.9 H cm /

17.2 x 16.3 x 25.6 in

Shipping Box

76.5 H x 50.0 W x 55.5 D cm /

30.1 x 19.7 x 21.9 in

Product Weight

18.3 kg [40.4 lb]

Frame Construction

Aluminum Die Cast Base

Extruded Aluminum Uprights

Steel Weldment Gantry Frame

Temperature Control

Circulating Heated Chamber

Product Weight

29.5 kg / 65 lbs

Shipping Box Weight

37.1 kg / 81.7 lbs

Build Plate

Flexible Steel Build Plate

Build Surface

Reusable Grip Surface

Display

5″ Full-Color Capacitive Touch Screen

Camera Resolution

640 x 480 pixels

ELECTRICAL

Connectivity

USB Drive, USB, Ethernet, WiFi

Power Requirements

METHOD

100 – 240 V

3.9A – 1.6A, 50 / 60 Hz

400 W max.

METHOD X

100 – 240 V

8.1A – 3.4A, 50 / 60 Hz

800 W max.

Warranty

Free 1-Year Extended Warranty

Support Plans

MakerCare Gold (2 Years)

MakerCare Platinum (3 Years)

SENSOR SUITE

21 Sensors including:

Drawer

Temperature

Humidity Control

Material Detection

RFID

Performance Extruders

Temperature

Material Detection

Encoder (Jam Detection)

Printer

Lid – Open/Closed

Door – Open/Closed

Temperature Sensors – Heated Chamber

Calibration Sensors

EXTRUDER HARDWARE

Extruder Thermal Core Length

48.2 mm

Max Extruder Drive Torque

200 Newtons

Nozzle Diameter

0.4 mm

MATERIALS

Spool Type

Smart Spools with RFID sensors

Spool Sensors

Remaining Material

Material Color

Material Kind

Supported Materials

MakerBot Precision Materials: ABS, ASA, PLA, Tough, PVA, SR-30

MakerBot Specialty Materials: NYLON, PETG, more to come

SOFTWARE

Software Bundle

MakerBot Print, MakerBot Mobile

Supported File Types

MakerBot (.makerbot), STL (.stl), SolidWorks (.sldprt, .sldasm), InventorOBJ (.ipt, .iam), IGES (.iges, .igs), STEP AP203/214 (.step, .stp), CATIA (.CATPart, .CATProduct), Wavefront Object (.obj), Unigraphics/NX (.prt), Solid Edge (.par, .asm), ProE/Creo (.prt, .asm), VRML (.wrl), Parasolid (.x_t, .x_b)

Operating Systems

Windows (7, 10)

Mac OS X (10.9+)

Contact Us

Phone

Find Us

HEAD OFFICE: 40 Koornang Rd, Scoresby

Victoria Australia 3179

3D Printers Australia : Melbourne, Adelaide, Brisbane, and Sydney

Designed by Kiodo Design & Marketing

Designed by Kiodo Design & Marketing